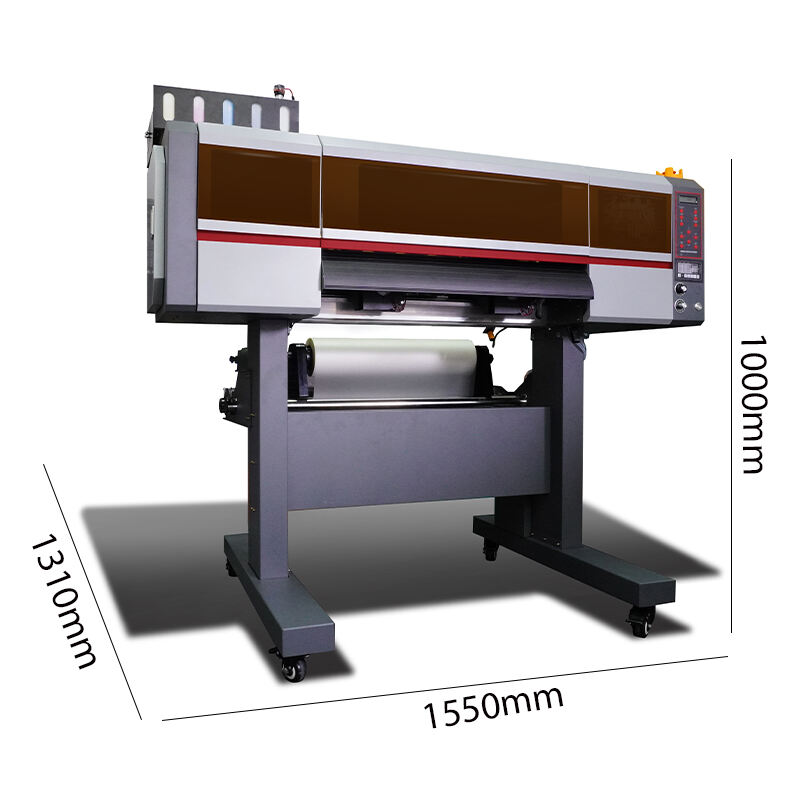

Introducing the Titanjet 2025 DTF Printer, a cutting-edge technology that allows you to easily create stunning designs on t-shirts with foil and flocking effects. This innovative printer features a 60cm (24inch) printing width, making it ideal for a wide range of t-shirt sizes

The Hybrid Tech of the Titanjet 2025 combines the best of both worlds, allowing you to seamlessly switch between foil and flocking printing techniques with ease. Whether you want to add a touch of shimmer with foil or create a fuzzy, textured design with flocking, this printer has you covered

One of the standout features of the Titanjet 2025 is its Powder Auto-Cycle Shaker, which ensures consistent and even distribution of powder for flawless prints every time. Say goodbye to clumping and uneven coverage – with this feature, you can achieve professional results with minimal effort

The built-in purifier of the Titanjet 2025 ensures that your workspace stays clean and free of excess powder, making for a more efficient printing process. With this purifier, you can focus on creating your designs without worrying about mess or cleanup

Not only does the Titanjet 2025 deliver exceptional print quality, but it also offers unbeatable convenience and ease of use. The intuitive interface makes it simple to navigate and adjust settings, while the durable construction ensures long-lasting performance

Whether you're a seasoned printing professional or a newcomer to the world of DTF printing, the Titanjet 2025 is the perfect choice for all your t-shirt design needs. With its advanced features and top-of-the-line performance, this printer is sure to take your creations to the next level

The Titanjet 2025 DTF Printer is a versatile and reliable solution for creating eye-catching designs on t-shirts. With its innovative Hybrid Tech, Powder Auto-Cycle Shaker, and built-in purifier, this printer offers exceptional quality and convenience in one compact package. Elevate your t-shirt printing game with the Titanjet 2025 – the ultimate tool for bringing your designs to life

Titanjet DTF Printer can do Foil Color+Flocking Color only at One Time Printing

This model is very easy to operate, don't need to make plate, foil and flocking colors all finished at one-time-printing, don’t need to cut, alignment calibration and will not harmful to the environment

Widely Applied to 99% Fabrics

Suitable for Nylon, Chemical Fiber, Cotton Cloth, Leather, Swimsuit, Diving Suit, PVC, EVA, etc

Our Titanjet DTF Printer Combined with Hybrid Tech to do CMYKW + Foil + Flocking Multiple Colors

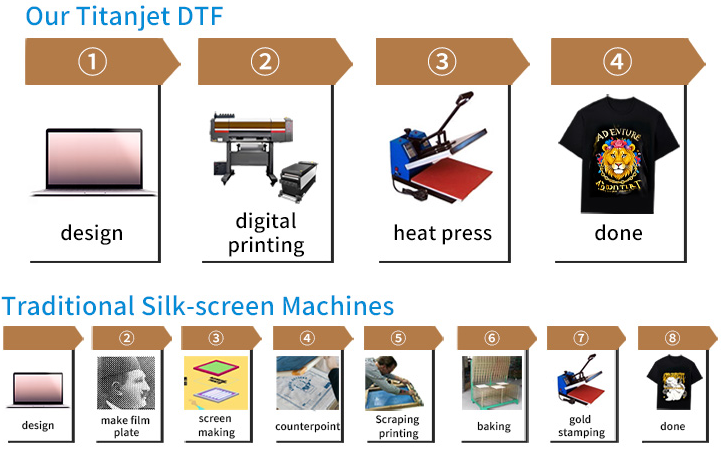

Normal DTF usually to do CMYKW colors on T-shirt, and if need to do Golden Color or Flocking Effect usually use the Silk-screen machine, and its process is very complicated and it's harmful to the environment. While Our Titanjet DTF Printer Combined with Hybrid Tech, only 4 steps as folllowings:

Titanjet Research&Develop HYBRID Tech combined with HYBRID Ink, HYBRID varnish and UV LED Curable Tech for DTF printer to realize FOIL and FLOCKING Effect all-in-one machine, don't need to make plate and don't cause anything harmful to the environment, only at one-time-printing.

1 head to print with HYBRID Color Ink;

1 head to print with HYBRID White Ink;

1 head to print with HYBRID Varnish

Advanced Setting to avoid of printer head blocking

Equipped with White Stirring System and White Ink Cycle Pump to avoid of White Ink Precipitation and then to avoid of heads blocking

(1) Head Board Heating System(2) Damper System to ensure the printing will not influenced by the pressure and temperature, so with these Double Heating System can ensure printing much more stably

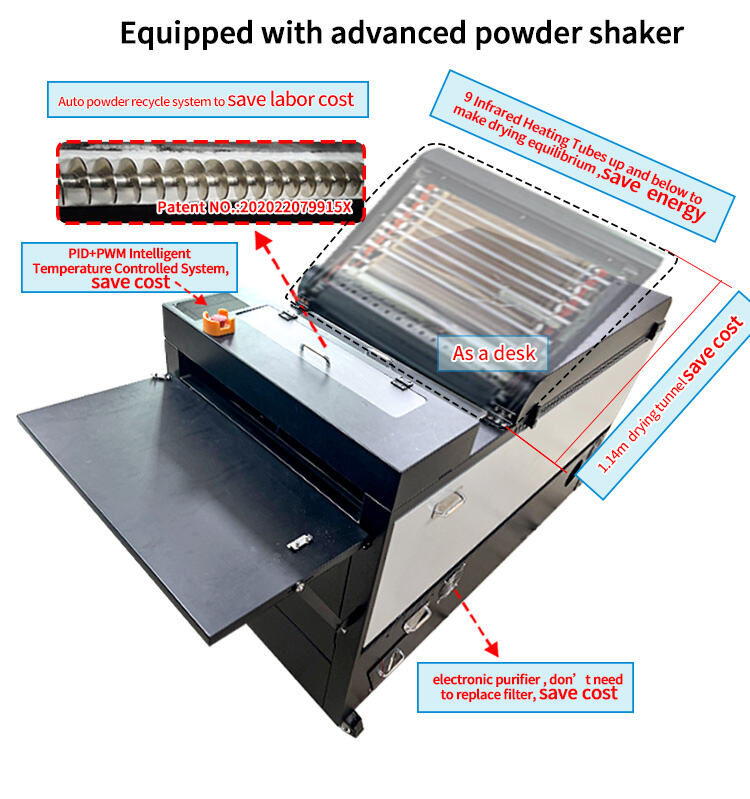

Equipped with Advanced Powder Shaker

(1) with advanced PID and PWM intelligent

(2) Auto-recycle powder shaking function to save labor cost

(3) Built-in purifier and don't need to replace filter to save cost

(4) 2 films vacuums built outside to ensure energy can not be taken away and can saved energy inside;

(5) 9 infrared heating tubes built up side and below side to ensure baking double sides and can drying more completely to save energy

(6) extended drying tunnel 1.14 meters to ensure baking more completely to save energy;

(7) without a exhaust tube in the top, the powder shaker can be used as a desk

Product Name: |

DTF Printer can do with FOIL and Flocking Effect |

Print Head: |

3 pieces Epson Heads |

Board Card: |

Hoson Board |

RIP software: |

Flexi Photoprint Software |

Speed: |

Production Mode: 6㎡/h, Quality Mode: 3.5㎡/h

|

Power: |

2500W, 50-60Hz, 110V/220V, |

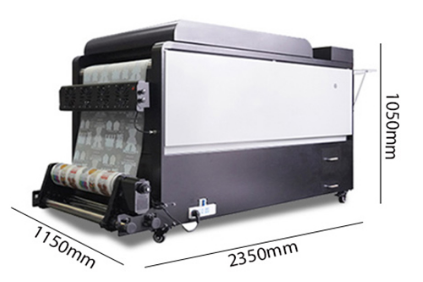

Package Size: |

L1900*W760*H760mm |

Weight: |

N.W.: 145KG, GW 190KG |

Product Name: |

Auto-recycle DTF Powder Shaker Built-in Purifier |

Power: |

7000W, 110V/220V |

Package Size: |

L1970*W1000*H1300mm |

Weight: |

N.W.: 285KG, G W.: 358KG |

1. How to make Foil+ Flock effect? Please could you tell me in details-- Here we use hybrid technology, that means hybrid CMYKW inks and hybrid varnish instead of normal DTF inks, and the powder glue and PET film is the same with normal DTF printing, also need 3 heads, 1 for hybrid CMYK ink,1 for hybrid White ink, and 1 for hybrid varnish, and also need heat press, while here need to note that it need to do 2-3 times heat press, first heat press with the PET film, and second heat press with Foil, and third heat press with Flock, and drying by powder shaker machine, all process finished.

2. What is the difference between this DTF Foil+ Flock application and Traditional Golden Stamping on textile

Traditional Golden Stamping usually use silk-screen technology, which process is very complicated and high cost and harmful to the environment. While DTF printer with FOIL + FLOCK effect: 1. easy to operate, can do FOIL color + FLOCK color at one-time-printing and don’t need to do alignment calibration, 2. Flexible to operate, can print for small order or even 1 piece T-shirt immediately, 3. the printing cost only $0.2 per T-shirt, much lower than silk-screen technology.

3. How about DTF Foil + Flock washing fastness

DTF Foil + Flock washing fastness is almost the same with silk screen golden stamping

4. The ink/PET Film/powder glue of DTF Foil+ Flock application is the same with normal DTF ink/PET Film/powder glue

It is different, DTF to do foil and flocking combined with hybrid tech and need to use hybrid ink, hybrid varnish and UV LED to ensure the ink curable, and need foil and flocking film to heat press. Other materials and process is the same with normal DTF

5. What is the Printing Cost

It is much cheaper than silk-screen golden stamping, printing cost (including all ink, varnish, foil, Powder GLUE, PET film and flocking film) is only USD0.2 for one T-shirt

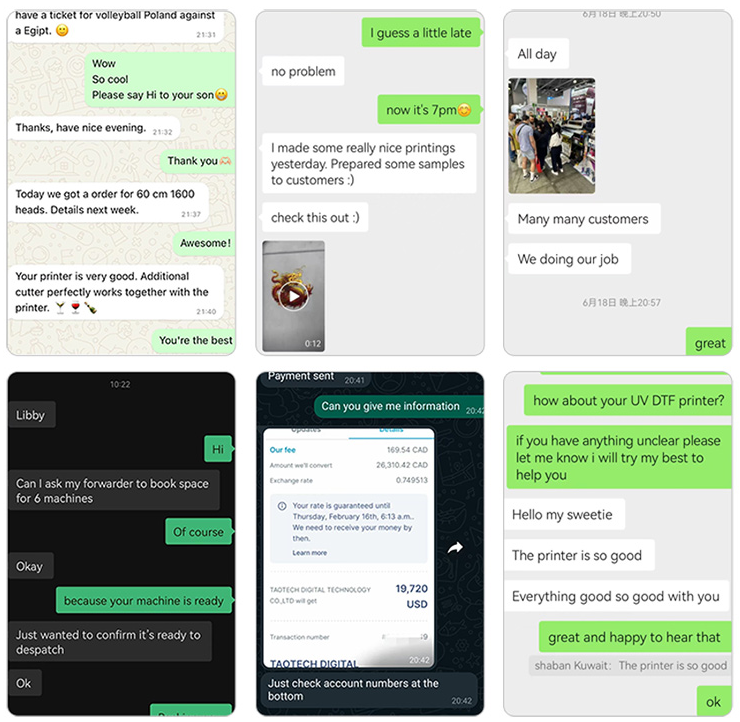

Our Titanjet has been specializing in R&D Serials of Digital Printers Since founded in 2006. Main Products including DTF Printers, Powder Shaking Machines, UV DTF Printer, Eco Solvent Printer, Sublimation Printer, UV Hybrid Printer, Super Latex Leather Printer, etc. We are always adhering to "Leading Role in Printer Innovation, Good Service to Every Customer. With high-quality products, good reputation and good after-services, it has won customers’ trust. Especially DTF Printer has gained a high market share and become an advanced brand in the Euro&USA markets

Titanjet has gained ISO9001 Standard Certificates, and CE, ROHS, EAC, UKCA, CBA&IEC, etc. Certificates

Titanjet attend Well-known International Exhibitions such as DRUPA, FESPA, DPES, APPP, TSCI, Euro Label Expos, etc.